Equivalent units of production weighted average method explanation, formula and examples

For deeper understanding, review Classification of Costs, Methods of Costing, and Manufacturing Account. Find examples of these costs in actual business by checking cost sheets and manufacturing accounts provided at Vedantu. If a bike manufacturer spends Rs. 800 per bike on materials and Rs. 200 per bike on direct labor, the prime cost per bike is Rs. 1,000. As you examine the diagram, think of the amount of water in the glasses as costs that the company has already incurred. To conversion cost of the chair will neglect any costs related to the material that goes into the production of the chairs.

Conversion Cost Formula Explained: Easy Guide to Calculate & Reduce Costs

Cost Per Conversion measures how much it costs to achieve one successful action within a campaign, like a sale or sign-up. It tracks the average online bookkeeping spend required to generate a desired outcome, helping marketers assess the financial efficiency of their ad efforts. This includes wages, salaries, and all the benefits paid to your production workers. No rocket science here; just tally up the payroll for those hardworking folks on the factory floor.

- This tool simplifies the process, making it easier to understand and monitor your conversion costs on a regular basis.

- With labor at $25,000, utilities at $10,000, and rent at $5,000, the conversion cost is $40,000.

- To complete a product, prime cost includes both direct material and direct cost, whereas conversion cost does not.

- During June, Excite Company’s prime cost was $325,000 and conversion cost was $300,000.

- Using easy-to-understand visuals like charts, graphs, or trendlines, illustrates insights gained over time and across various campaigns, making the data digestible at a glance.

- By analyzing the sum of direct labor + manufacturing overhead costs, companies can identify inefficiencies and implement corrective measures to enhance productivity.

Examples of Conversion Costs

- For shipping the raw materials to the desired location, they paid ₹30,000 to the transportation company.

- Understanding conversion costs is vital for businesses to maintain competitiveness and profitability in the manufacturing industry.

- Direct materials is the basic physical ingredient, matter or substance which CARES Act the company processes to make a salable product.

- How do companies keep track of their expenses, production, sales, and efficiency?

- Changes in regulatory requirements are uncontrollable, and the entire industry can be affected by them.

Basically, it’s the whole shebang of getting a product from a mere concept to something you can actually hold in your hands. Conversion costs are a cost accounting phrase that refers to the sum of direct labor costs and manufacturing overhead costs. In other words, conversion costs are costs incurred by a manufacturer other than the cost of direct materials. Understanding conversion costs is crucial for evaluating production efficiency and managing manufacturing expenses. Conversion costs encompass the expenses related to transforming raw materials into finished products, highlighting direct labor and manufacturing overheads.

Examples of prime cost and conversion cost

In the world of manufacturing, the conversion cost is a vital metric that helps determine the total cost of turning raw materials into finished products. Understanding and calculating this cost is essential for businesses to ensure they can accurately price their products and manage their operations efficiently. This article will explore how the Conversion Cost Calculator works, explain the formula, offer an example, and provide helpful insights for users.

- This information helps managers know where to focus their attention when planning, directing and controlling costs.

- This article explains the computation of equivalent units of production under the FIFO method.

- Basically, it’s the whole shebang of getting a product from a mere concept to something you can actually hold in your hands.

- Similarly, when calculating the conversion cost of a product, the production or factory overheads of the product are considered.

- The direct material cost of the chair will include $5 paid to the assembly worker and $2 paid to the paint and polish worker.

Examples of direct labor include assembly line workers, machine operators, and technicians. Calculating direct labor costs involves multiplying the total hours worked by the applicable wage rate, including any additional benefits or allowances. Therefore, once the batch of sticks gets to the second process—the packaging department—it already has double declining balance depreciation method costs attached to it.

In this post, we will define conversion cost, conversion costs formula describe common ones that a business may face, the formula for calculating it, and provide examples of how to use it for accounting in your firm. The expenses incurred in transforming raw materials into completed products are known as conversion costs. This concept is used in accounting costs to deduce the value of ending inventory reported in the balance sheet. Conversion costs are a metric that can also be used to understand the incremental costs of creating a product. When the component costs and the conversion costs of a product are combined, they represent a lower threshold value at which the product is generally sold.

Discover the Power of Sourcetable for All Your Calculation Needs

- Understanding how to calculate conversion cost is crucial for businesses focusing on optimizing production and marketing strategies.

- For example, analyzing Cost Per Conversion monthly or weekly reveals patterns that influence its performance.

- To find the profits related to specific products, it is important that the costs of these products are known.

- The \(6,500\) units completed and transferred out to the finishing department must be \(100\%\) complete with regard to materials and conversion, so they make up \(6,500 (6,500 × 100\%)\) units.

- Conversion costs, which also include direct labor and manufacturing overhead, are equally important as they help businesses assess production efficiency and identify areas of waste.

- All these expenditures are aggregated and divided on the number of units produced to find the cost per unit of a single product.

- One of the most important pieces of information you can get from the values of conversion cost is whether your marketing campaign is profitable and, therefore, worth the effort.

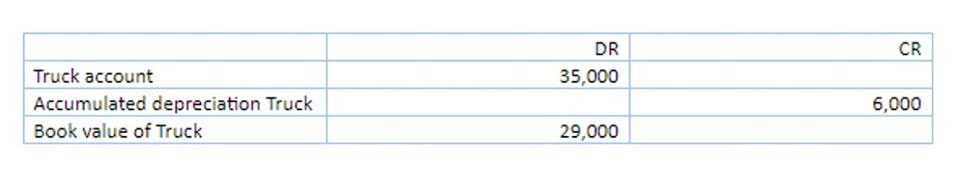

In terms of direct labor, prime costs overlap with conversion costs but emphasize labor’s role in transforming conversion costs raw materials into finished goods. In the table above, the direct labor costs and manufacturing overhead for Company XYZ are listed along with their respective amounts. The 1,200 ending work in process units are only 35% complete with regard to conversion costs and represent 420 (1,200 × 35%) equivalent units.

Cost Control

Prime costs are reviewed by operations managers to ensure that the company is maintaining an efficient production process. Sometimes that knowledge leads to management’s decision to stop production, but sometimes that decision isn’t as simple as it seems. The cost to produce a penny is more than one cent, and yet, the United States still makes pennies.

Leave a Reply